Galvanized metal is a compound metallic style in which muffling stage of view created through steel and zinc layering. Important as the zinc content is this helps prevent rust from forming and keeps metal safe. Our most popular material: galvanized metal, which includes construction usage and automotive as well in additional requiring hand-tools. This zinc coating, however removes the fundamental grippy quality of steel; it makes handling a metal difficult. Here strip galvanizing comes for our rescue.

Strip galvanizing is done to take off all or some layers of zinc from the metal base. Therefore it is much easier to weld, because this lower temperature forms not too hardened and fragile material. In other words, there are 2 ways about this. By dropping your metal into a certain liquid you can remove the zinc layer in an easy chemical process. Alternatively, you may use a dezincification machine. This gives us a metal which can then be forged or moulded into any shape to suit the needs of a project.

Galvanized metal may carry a few undesirable things on it, like dirt or oil. These contaminants can interfere with the metal's conductivity so it does not function as well over time. The impurities that remain on the metal can affect its performance and service life, By this way we can discard these absorbances from, the materials which ultimately results in greater utilization of metals for much longer durations. These can be further dissolved by the zinc and impurities in a unique liquid or removed by hot rolling to get this metal pure.

Exposing steel to galvanize also makes the steel stronger and its life longer, so therefore by stripping it before going through processing becomes an advantage. Process where zinc island any impurities on the metal are eliminated, leaving a slate of clean steel. A surface which does not rust or corrode is much simpler to deal with than one that will become rusty, so this product has a variety of advantages. Storing your gas cans in a rusty old shed is the arch-nemesis of any steel that may have stood to last for years on end; its either keep it from rusting, or break out a new hundred dollar bill. Furthermore, we are available to use any metal for construction or machines by making it as easy and according to our need.

Metal that degrades from rust and corrosion over time… These facultative biofilters are moisture limiting and potential karogenic droplets in the air or h20 contamination. Strip galvanizing also protects the metal by keeping away moisture and other harmful things. The zinc coverage would work as a buffer, preventing water and the other damaging elements from affecting directly onto it. Part of this is the responsibility of Strip Galvanizing manufacturers, who can protect metal from rust and corrosion as long as the zinc coatingStrip galvanizing itself gets tarnished.

Relevant methods are to stripping ways of Zinc coating as this is indispensable. This is where one must be careful, to use the right tools so that nothing gets hurt in twine metal work. The approach you choose in removing the zinc will also be assembly-specific to the part we are producing as well. Sometimes the special liquid is your best option and others a machine would work fine. Using the appropriate process, we can get good results as galvanizing metal is very important for its right implementation.

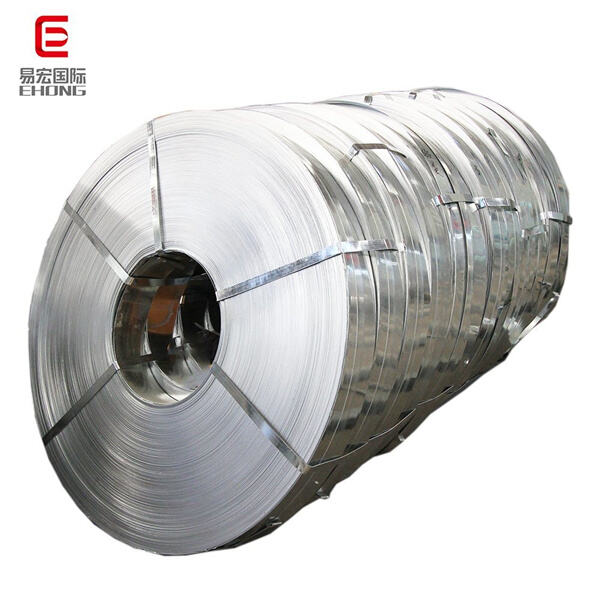

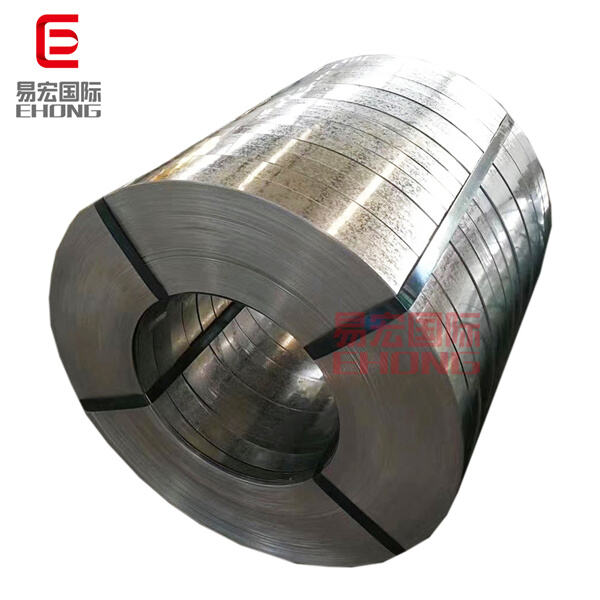

We strip galvanized over 17 years of experience in the export of steel and are able to provide a broad assortment of coils and profiles. There is also a group that is specifically focused on trade with foreign countries, and we can provide quick quotes, and offer the best solutions. The larger the order the more competitive our price!

Each product is inspected before being shipped. It is guaranteed that the product will be of high quality. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ galvanized/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, strip galvanized, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We can supply American/strip galvanized/Australian standard H-beams Japanese standard steel sheet piles and provide deep processing services such as punching and cutting Our products have been exported to Western Europe Oceania South America Southeast Asia Africa Middle East and other regions

Our strip galvanized team of foreign trade professionals is trained in their products They provides prompt quotes as well as high-quality customer service We also have an experienced sales team that can be customized for clients available 24 hours a week for all inquiries questions or solutions We're sure that we will be a trustworthy business partner to you