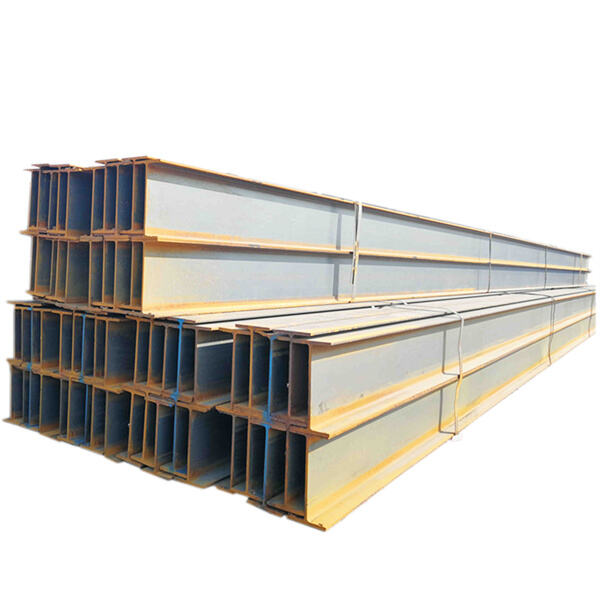

Steel I beams are extremely powerful and versatile materials that provide the backbone for virtually every commercial building in existence. These long metal bars aptly called I- may are often used in the construction of megastructures like bridges, factories and even skyscrapers. On the base level these are works as they perform to sustain building by providing exceptional support along no collapsing.

Steel I beams are the cornerstone of modern architectural design, since their inception in the mid 19th century. Their arrival was a game-changer in the construction sector, replacing vast quantities of still-used but aging materials such as wood and stone. This advancement allowed architects and builders to design taller, higher capacity and more spatially complex edifices with certainty about their ability to support the weight of these structures.

Steel I beams are versatile in nature. These versatile parts are used in a vast range of construction tasks that vary from minor residential decorations to massive commercial buildings. Whether used for supporting columns, framing structures or uprights underpinning a built structure steel I-beams are renowned as one of the most versatile materials available to construction project managers.

As a building material, there are benefits and drawbacks inherent in steel I beams. Chief of them all is their strength and resistance which may not be so difficult to achieve. Steel I beams can also support heavy loads and withstand weather, fire, pests so you know they are reliable. Moreover, the ease of their manipulation means that builders can cut them up and shape or weld them virtually any way they choose.

Steel I Beams - with a Catch Steel I beams are another thing that people love to use. Foremost among these are cost, as steel is generally more costly than other materials such as wood. In addition, the fact that steel is susceptible to corrosion means structures built with this forged composite material might fail over time due to structural damage.

That is true with efforts in construction to ensure the structural integrity of steel I beams. Steel I beams play a critical role in distributing and carrying that load throughout the building, proof of which lies in how buildings need to bear their own weight as well as those of occupants and equipment. Compliance with federal policies and standards are necessary to ensure safe installation and maintenance of steel I beams by practising thorough checks for symptoms and scrapes.

Summing it all up, steel I beams are one of the most important parts in modern construction work. They are extremely strong and durable, enabling the building of large complex structures yet versatile for a wide range of construction projects. While there are downsides to using steel beams, the advantages and structural integrity outweigh them all thus making steel I beam the preferred choice for builders as well as architects across continents.

We have over 17 years of experience in the export of steel and are able to provide a broad assortment of coils and profiles. There is also a group that is specifically focused on trade with foreign countries, and we can provide quick quotes, and offer the best solutions. The larger the order the more competitive our price!

Our expert team of foreign trade professionals is trained in their products. They provides prompt quotes, as well as high-quality customer service. We also have an experienced sales team that can be customized for clients, available 24 hours a week for all inquiries, questions or solutions. We're sure that we will be a trustworthy business partner to you.

We collaborate with several large steel mills, and all finished products undergo inspection before shipping, so that quality is assured. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ galvanized/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We can supply American/British/Australian standard H-beams, Japanese standard steel sheet piles, and provide deep processing services such as punching and cutting. Our products are currently exported to Western Europe and Oceania. They've also been shipped to South America, Southeast Asia. Africa, the Middle East and Africa.