Scaffolding planks are long, flat pieces of wood or metal. It is walked on or stood upon by workers. Scaffolding planks have a great relevant in construction; this is the material which used to help people as well as materials that are related, for building types of equipment they use it reach and high places there get impossible or difficult. They are mandatory items that reduce the labour to do and also make it all securee of construction work.

For supporting workers and their tools where there may be fall or trip hazards, a good scaffolding plank should safely perform this duty. These offers also need to be perfectly constructed, and made from correct materials that can manage these heavy loads. Light Weight-It needs to be light so that workers are able to easily transport and install it without breaking their back. A nice scaffold plank sets up and takes down easy A single useful point was that on this manner of production wherein you are out inside the discipline, creation laborers tend to circulate from one place to another quite speedy. For instance, making the plank easier to carry means that workers can spend less time simply holding on and more of their day doing actual work.

Things to note when choosing a plank for job site usage Firstly, the plank must be long enough so that it reaches an adequate height. If your string is too short workers will have no way of getting to the place where they need to be working. Second, the plank must be capable of being supported by workers and tools without deflection (even over its full 16' span!) or failing. Security is no small part of this. Finally, the board ought to be easy to get on and off itself while giving a stable footing. Safety is top of mind on a construction site.

Workers are able to work on Scaffolding planks in different height areas setBackground of a typical urban household-based hazard scene. Quicker... Safer Your workers can work faster and more efficiently when they are no longer required to access high places. This has significance for the construction sector, where lost time could translate into wasted money. Scaffolding planks also typically safer for workers as a lot of them provide a secure way to stand on. To get around this, the tracks are flanked by boards: otherwise workers would have walk along a narrow ledge, or on ladders and people might fall.

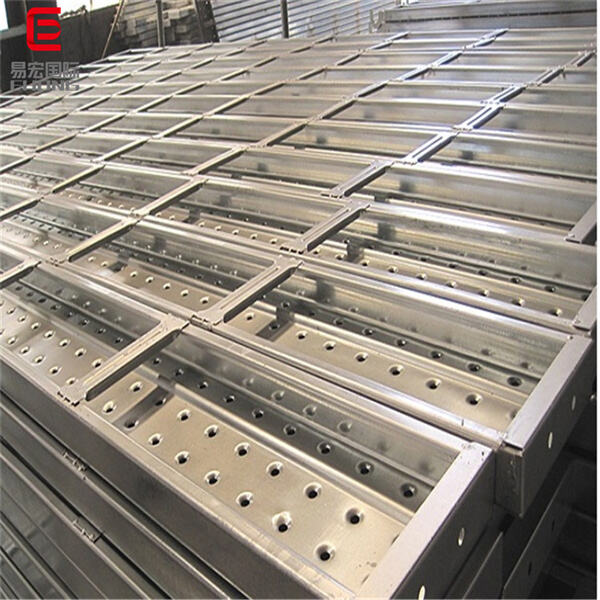

Today we can all while about there are so many different types of scaffolding planks for us to get our hands on. Metal and wooden planks Metal planks never fold, are nearly always more durable than wood but they can be much heavier to move around. Steel pipe is heavy and not lift-friendly as opposed to wood planks which are lightweight. However, they do not have the thickness of metal so each building or job needs to be evaluated its own specifications.

We have over 17 years of experience in the steel export business and we can supply a vast range of coils and profile. In addition, we have a group of foreign business leaders in trade, with a scaffolding plank, and can give you the most efficient solutions and services. The larger the order, the more competitive price!

We work with a number of large steel mills, and all finished products undergo inspection before shipment, quality is guaranteed. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ scaffolding plank/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We have a highly skilled scaffolding plank trade team with high product specialization prompt quotes and top-quality service We also have a skilled sales staff for customizing clients available 24 hours a week to answer any questions inquiries solutions and requirements We're confident that we'll be a trustworthy business partner to you

We can supply American/British/Australian standard H-beams scaffolding plank sheet piles and provide deep processing services such as punching and cutting Our products are currently exported to Western Europe and Oceania They've also been shipped to South America Southeast Asia Africa the Middle East and Africa