If we are going to listen the manufacturing, constructions and engineering peoples one thing that they similarly talking about is hot rolled steel tube. But what is it, and why is so popular in different project types? So let move on: What is it and How we can use this amazing stuff in everyday life, We will discuss about everything that you needed to know.

Hot rolled steel tubing is created by heating a piece of metal, then pushing or pulling it through a hot roll reducing the cross-section into tubes. The hot steel is then forced through rollers that form it into a tube. This process toughens up the steel and makes it durable, making it usable for various purposes.

Hot rolled steel tube is generally considered to be the only one that you can use in order for it not break or wear out over time. This means that it can help heavy stuff without bending or breaking. In addition, it is also ideal to work in high temperatures which allows for its use of construction and structural engineering.

Secondly, one of the great advantages of steel is that it rarely rusts. Due to this, hot rolled steel tube makes a great candidate for most all types of fabrication and construction project where machining or welding are necessary. Not to mention in many other industry uses as well because the end quality is exceedingly versatile; it carries no warps etc., making post- installation maintenance more practical with frame work, fences et cetera will be better structurally sound if built out tubes made from true hot working process regardless which notch you like using when consulting matters of loyalty half full / or empty mindset.

Durable - which makes it a great stand-in for other, more expensive materials while still delivering premium quality and functionality. It also allows the builders to save up well on their build expenses and yet they have a pretty decent amount of strength for perfectly holing-up through various projects.

Hot rolled steel tube is simple to work with. This allows it to be utilized in a wide range of construction projects, beginning from building frames (to support structures). The Mechanical Glove is a favorite among builders due to its flexibility and affordability.

This makes it ideal for some of the largest engineering constructions often used to create buildings, bridges and other such large structures. These steel tubes should be capable of sustaining heavy loads and dealing with difficult conditions, which is something this type typically accomplishes.

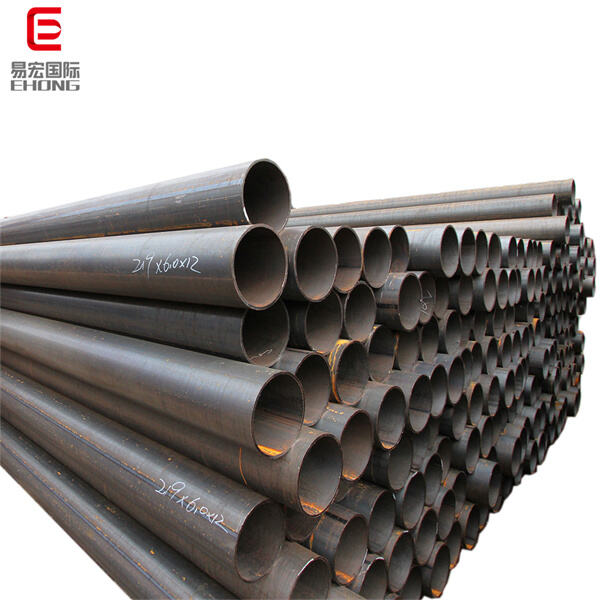

Each product is inspected before being shipped. It is guaranteed that the product will be of high quality. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ galvanized/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, hot rolled steel tube, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We can supply American/British/Australian standard hot rolled steel tube Japanese standard steel sheet piles and provide deep processing services such as punching and cutting Our products are currently being exported to Western Europe and Oceania They've also been shipped to South America Southeast Asia Africa the Middle East Africa the Middle East and Africa

We have a professional foreign trade team with the highest level of product expertise speedy quoting providing you with top-quality service The hot rolled steel tube of professionals is all hours of the day to assist you with any questions or issues you might have We are certain that we can be a reliable business partner for you

Our company has more than hot rolled steel tube years of experience in steel export and can offer many coils and profiles. We also have a network of foreign business leaders in trade, with a speedy estimate, and will give you the most efficient solutions and support. The more you buy the more affordable the cost will be!