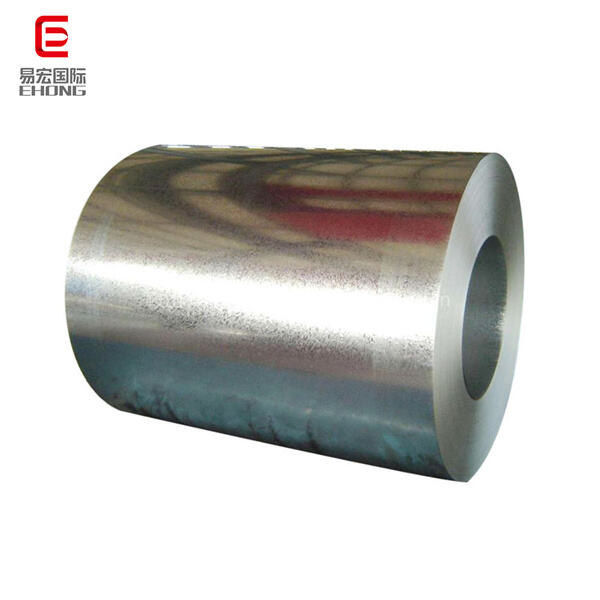

GI coils, which are known as Galvanized Iron Coils, have several uses across different industries because they act as metal coils that many products require for their manufacturing processes. These coils are made mostly of iron and within this sometconsequently coated in zinc as well so that they do not rust. GI coils are prepared by galvanising iron and then they were rolled to flatten them into flat sheets or slitting the same in some other possible way because it is used for different purposes in industrial areas.

Considering the heavy-duty construction and lash resistance of GI coils it is vigorously used in industrial use. Due to their ability to withstand extreme environmental conditions, like moisture or high temperature without experiencing deformation makes it a perfect material for industrial boilers and furnaces. In addition to that, GI coils have an impressive corrosion-resistant properties hence they are a great alternative for various applications in construction and electronics industries.

GI coils are widely applicable in the construction industry for making roofing sheets, gutters and fencing as they have high durability to sustain harsh weather patterns. Similarly, in the electronic space, these coils are key to how wire products and electrical components are made. On the other hand, GI coils have a protective layer of zinc coating that prevents oxidation, and fail to experience any kind of corrosion which may otherwise prevent them from having high electrical conductivity.

GI coils are also available in different grades and finishes, making them the most versatile amongst other types. The coils are available in several grades, such as commercial grade (CS), lock-forming quality (LFQ), deep drawing forming-quality and structural surfaces. These components are the backbone of modern industrial production and other important thing in which grade, finish determines because according to Gauge application can vary drastically.

Overall, GI coils are an essential for all types of industrial applications that demand strength and long-term corrosion resistance. Their versatility in numerous industrial applications, and their effective resistance to oxidation and corrosion has widely lent them importance in the construction industry and electronics. Offering a variety of grades and finishes, GI coils prove to be an adaptable means for customization in any industry that helps the sector meet its specific needs further establishing itself as one among those most foundational items amongst all contemporary industrial practices.

We gi coil over 17 years of experience in the export of steel and are able to provide a broad assortment of coils and profiles. There is also a group that is specifically focused on trade with foreign countries, and we can provide quick quotes, and offer the best solutions. The larger the order the more competitive our price!

We have a highly experienced foreign trade team that has excellent product knowledge quick quotes and top-quality service The sales team of professionals is always available to gi coil any questions and concerns you might have We're sure that we can be a reliable business partner for you

We work with a number of large steel mills, and all produced products are inspected prior to shipment, quality is guaranteed. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ galvanized/gi coil/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

gi coil can supply American/British/Australian standard H-beams Japanese standard steel sheet piles and provide deep processing services such as punching and cutting As of now our products have been sold to Western Europe Oceania South America Southeast Asia Africa Middle East and various other regions