Setting up Corrugated Tubes for Your upcoming large-scale project. Corrugated pipe can be utilized for highway/road construction projects. Most of them are well known for being strong, flexible, and cost-effective; Primary Applications of HDPE Pipes. In this article, we will provide a comprehensive manual on installing ehong steel ERW Steel Pipe for your upcoming project, starting from preparing the site to addressing environmental issues.

However, it is crucial to determine the destination of your drain before you begin the installation process. Tidy up the space by clearing out any rocks or tree roots, level it, and it will be all set for laying down your patio. Measuring the Tube: Ensure Your ehong steel Hot Rolled Steel Pipe is the Right Size Before installing, accurately measuring and sizing the pipe is crucial to ensure proper fit.

The process of ditching is essential when installing your deck. A trench larger and deeper than your pipe dimensions, with a slope of at least 2-5 mm per meter, or appropriate pitch for water drainage in the drain system. Position the ehong steel Cold Rolled Steel Pipe in the trench that was recently dug, making sure it is aligned with the direction of drainage you want and with the bell end pointing upstream.

Any necessary additional fixtures such as elbows or tees to ensure proper junction from one end of the system to the other. Install the ehong steel Seamless Steel Pipe in its designated location, connect it to the main drainage system.

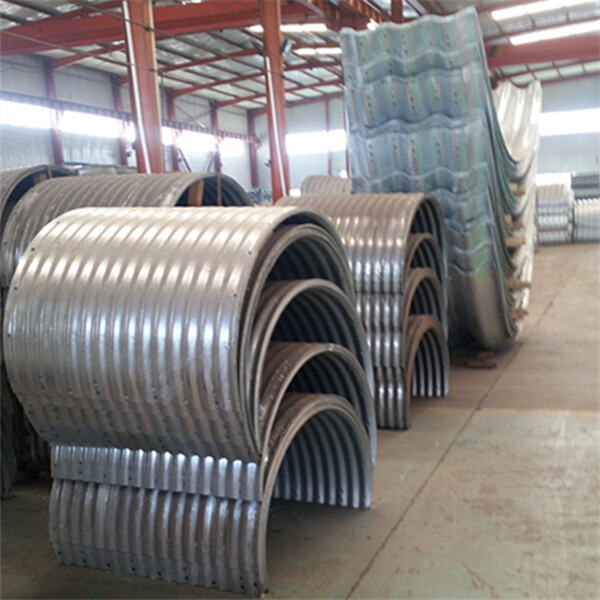

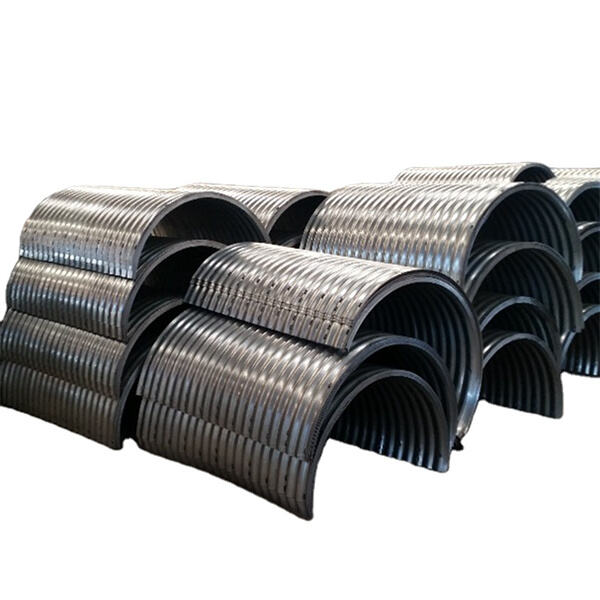

Once the initial 8-foot individual enters, ensure that your pipe is securely in its position. The soil balance should be distributed in lifts around the pipe and compacted to prevent any movement or settling that could disrupt its buoyancy support. Different types of ehong steel Spiral Steel Pipe exist. Different types of corrugated pipes are made for various uses and applications. Common types include single wall corrugated pipes used for non-pressure applications such as drainage. Double Wall Corrugated (DWC) Pipe: DWC is perfect for pressure uses like sewer/wastewater and stormwater drainage, or replacing problematic construction materials. Perforated Corrugate Pipe: The most commonly used pipe in subsurface drainage systems is the perforated corrugated pipe, which permits water entry while restricting soil penetration. Durable Large Diameter Corrugated Pipe: This innovative of new structure is created to endure for a lifespan of 100 years, serving as an intricate pathway with an operational water system for stormwater control and irrigation via the sleek inner surface. Advantages of Using Corrugated Drainage Systems. Advantages of this pipeline design for utilization in drainage systems. Flexibility: These pipes have high flexibility, enabling them to easily bend as needed from the surface. Great for tough conditions, able to withstand corrosion, abrasion, and chemical harm. Expense: Cheaper than materials such as concrete, PVCs, metals, and similar substances. Installation speed: Typically, lightweight solutions require fewer heavy tools and can be installed more quickly than heavier system implementations. Promoting Green Living with the Use of Corrugated Pipes. Considering environmental issues, there are methods to utilize corrugated pipes in an eco-friendlier way. Where They Make Pipes from Reused Materials to Help Conserve Earth's Resources Without Intentionally Wasting Them. Work together with manufacturers to encourage the use of sustainable energy and water methods in manufacturing operations. Sustainable reuse and recycling of old pipes help decrease landfill waste while also promoting circular economy principles. In conclusion, corrugated pipes are crucial for nearly all construction projects due to their optimal mix of strength and adaptability paired with affordability. By incorporating environmentally friendly techniques in your construction projects and selecting the appropriate corrugated pipe systems for drainage, you can achieve a drain that is not only dependable but also environmentally conscious, thereby covering all aspects of sustainability.

Our company has more than Corrugated pipe years of experience in steel export and can offer many coils and profiles. We also have a network of foreign business leaders in trade, with a speedy estimate, and will give you the most efficient solutions and support. The more you buy the more affordable the cost will be!

We work with a number of large steel mills, and all finished products undergo inspection before shipment, quality is guaranteed. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ Corrugated pipe/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We have a highly skilled Corrugated pipe trade team with high product specialization prompt quotes and top-quality service We also have a skilled sales staff for customizing clients available 24 hours a week to answer any questions inquiries solutions and requirements We're confident that we'll be a trustworthy business partner to you

We can supply American/Corrugated pipe/Australian standard H-beams Japanese standard steel sheet piles and provide deep processing services such as punching and cutting Our products have been exported to Western Europe Oceania South America Southeast Asia Africa Middle East and other regions