It is only starting to chill outside considering that the cold months get there around. Cold rolled steel tubing is used as well, when people build thing they expect to stand up in the chill of winter. This is because the steel sitea in it has been heat-treated, modified so that would become much stronger than regular stocks and endure lots of wear. As the name suggests, cold rolled steel tubing is a type of product made from very strong and durable material. You will find this everywhere; it might be used in making your house or building etc., you may have been using cars today which are also manufactured through these materials inside so basically they play an important role in all machine productions. The following is a re-post of an email Tom wrote on the many virtues cold rolled steel tubing — what made it great, where it was useful and why we used outside so much… oh yeah, that environmental thing as well.

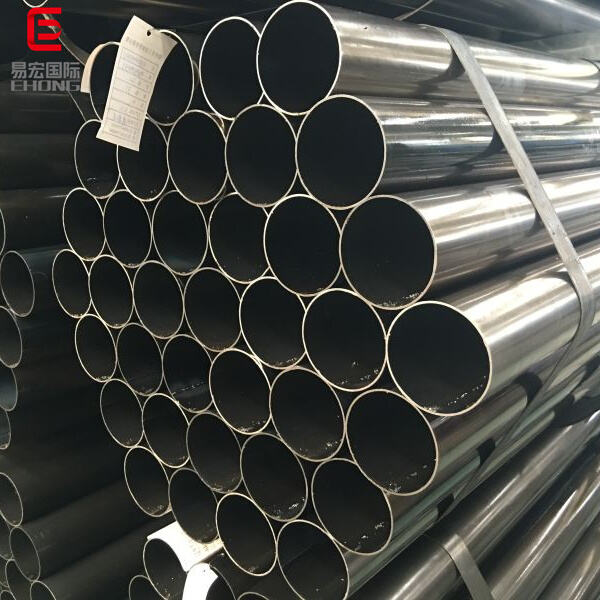

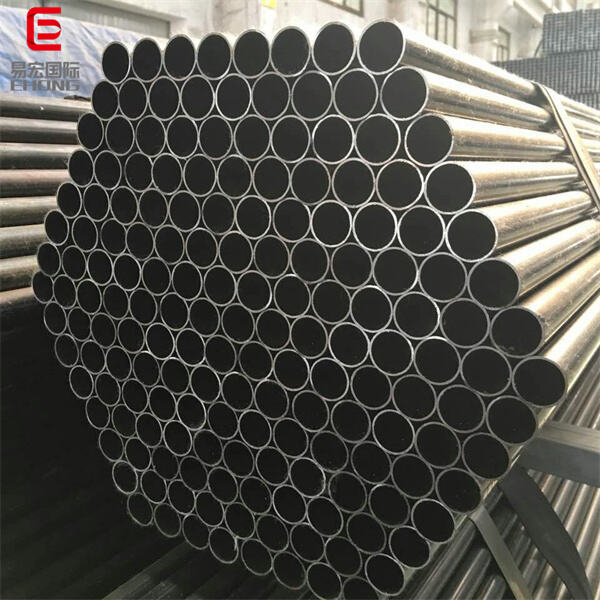

Cold rolled steel tubing possesses numerous attributes which make it an ideal for many kinds of projects. Its biggest advantage would, therefore, be its resilience. Cold Rolled steel: Cold rolled steel is 24x stronger than traditional painted and laminated tubing as it undergoes a special treatment that makes it hard. This makes it suitable for places where normal steel is not strong enough to sustain. Another advantage of cold rolled steel tubing is the fact that it would not simply rust, corrode and lead to pitting. This is extremely crucial because long-term rust can start to deteriorate steel. Indeed, as we pointed out above the cold rolling steel tubing is treated under a special treatment which leaves an anti-rust and corrosion coating on it that makes sure to protect from others rusting and keep its pliability for long years of continuous usage.

Cold rolled steel tubing is everywhere, and it serves many needs. Now a days it is one of the most commonly found place in construction Industry. A kind of cold rolled steel tubing, builders use it to build massive objects such as bridges and buildings that we depend on literally each day. In the transportation industry, cold rolled steel tubing is also a familiar product. It is used to make parts in a wide range of vehicles from cars, buses and trucks through trains. Cold rolled steel tubing is also used in factories and manufacturing plants that rely on its strength to produce different components for the numerous machines/equipment we depend on today.

How to manufacture cold rolled steel tubing? This is manufactured by cold rolling. This is a step where steel rod pushes out of expected Section through some set of rollers in very cold condition. It flattens the steel, disposes of ruts and apportions strength to it. Once the steel is shaped, it needs to be cut into the proper sizes and forms for the intended use. After cutting the steel, it undergoes a coating which will protect against rust and corrosion. All of this care and attention means that its finished article is sturdy and long-lasting.

For outdoor use cold rolled steel tubing is great. It is less prone to corrosion, a much needed feature in anything that faces the outside elements. Cold rolled steel tubing is known for offering excellent strength and durability as well, which makes it a great option to use in various type of outdoor applications such as fences, gates, and even some types of outdoor furniture. It is also applied in the creation of other outdoor structures such as bridges, walkways and playgrounds. Its robust and durable build makes cold rolled steel tubing able to withstand harsh weather conditions like rain, snow or extreme temperature changes that is why it suitable for outdoor projects.

This new use of cold rolled steel tubing is also very good for the environment. This is because this type of steel endures more than normal. This is an important factor that comes from the amazing abilities of it so people don't need to get new one more often than needed and thus less steel needs to be made and produced. It helps to save the environment from evil of steel industry. The rust protection coating that is generally applied to cold rolled steel consists of materials that are environmentally safe. Moreover, it is another way of minimizing the environmental burden related to this kind of steel.

We cold rolled steel tubing supply American/British/Australian standard H-beams Japanese standard steel sheet piles and provide deep processing services such as punching and cutting Our products have been exported to Western Europe Oceania South America Southeast Asia Africa Middle East and many other regions

We have a highly experienced foreign trade team that has excellent product knowledge quick quotes and top-quality service The sales team of professionals is always available to cold rolled steel tubing any questions and concerns you might have We're sure that we can be a reliable business partner for you

Each product is inspected prior to shipping. Quality is guaranteed. The main products are all kinds of steel pipes cold rolled steel tubing/SSAW/LSAW/ galvanized/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We have 17 years experience in the export of cold rolled steel tubing and can provide a wide variety of profile and coils. We also have a team that is specialized in international trade. We offer quick quotations, and also provide the best solutions. The more you order, the lower the cost!