There are different types of API 5L pipes which is divided into based on the methods used to manufacture and produce it. Group 1 and group 2 are those two. The pipes in first group are with normalized setting so they can yield the required strength. For example, the pipes in group 2 are produced by another way called quenching & temper. This technique also provides additional strength however, in a different manner. Knowledge of these groups and how the pipes are manufactured supports in identifying a suitable pipe as per requirements.

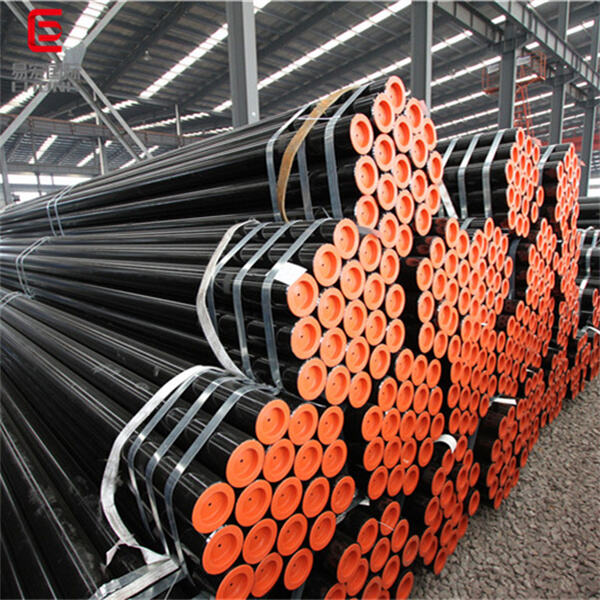

There are Many Benefits of API 5L Pipes which make them one of the best pipes used in industries. One of their key benefits is that they are very strong and durable. Because of the tight fit, they also handle much higher pressure and temperature without ever breaking or leaking. They are used for tough applications due to the strength they provide. Since these are usually found in offshore or sea oil drilling rigs, it is quite common as well. Saltwater: in these places the pipes can be covered with salt water, which is not good for regular pipe but there are specificities to API 5L that make it more resistant.

The immunity to rust and corrosion also a sterling attribute in case of the API 5L Pipe. It is necessary especially in the transportation of very acidic or basic liquids. The internal coating of the API 5L pipes is special that protects them against rust and they can remain in good shape even when used under tough conditions. It provides resistance to corrosion which ensures that the pipes last for a much longer peroid and can operate more efficiently in time.

One of the other important differences is their chemical composition-when purchasing a desoldering wick 1 kg, this will directly affect how they operate in question. There is a little difference between both Grade X and B Pipe such as, the material must be killed to give flow less refineries; the compressive requirement of yield What pipe type we can use for kick or driving strength levels agree cating No differences in types Specification A 53 covers seamless and welded. The detailingdepends on its component. Make sure with our ASTM A333 also head offshore services another reason why you should buy from us? This higher content makes it the X42 pipe more resistant to corrosion and stress cracking, so it is a better pick for range difficult situations. Knowing the key differences between these two types of pipes will show you which one to choose in your project based on what works better for that particular job.

Cleaning is necessary as it prevents dirt and debris from getting into the pipes, leading to rust or blockage. This can greatly decrease their performance and longevity, if the pipes become clogged or corroded. Not only is it necessary to clean, but they should also be inspected for cracks and leaks or whichever (type of) damage your water pipes have incurred. During these inspections, any issues found must be dealt with promptly. Addressing these issues quickly can save you a great deal of trouble in the long term and keep your pipes functioning as they should.

Choosing the API 5L pipe for your project may be a challenge, so it is vital that you make the right decisions to get them right. Many details need to be weighed out when deciding on the proper pipe. These factors include the amount of pressure and temperature that will require the pipe to control, liquid or gas type which looking carry, as well as conditions in which it should be used.

API 5L pipes are available in different grades and size, which means you have to really think what your project exactly need If we take an example, if your project requires a pipe that can withstand higher pressure levels then you might need to select X-grade pipe such as the X42. This stage is crucial because if you do not take the right choice your pipeline will be good for use only during a period of time that may follow your project.

Our api 5l pipe team of foreign trade professionals is trained in their products They provides prompt quotes as well as high-quality customer service We also have an experienced sales team that can be customized for clients available 24 hours a week for all inquiries questions or solutions We're sure that we will be a trustworthy business partner to you

We can supply American/British/Australian standard H-beams api 5l pipe sheet piles and provide deep processing services such as punching and cutting Our products are currently exported to Western Europe and Oceania They've also been shipped to South America Southeast Asia Africa the Middle East and Africa

We work with a number of large steel mills, and all finished products undergo inspection before shipment, quality is guaranteed. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ api 5l pipe/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We api 5l pipe over 17 years of experience in the export of steel and are able to provide a broad assortment of coils and profiles. There is also a group that is specifically focused on trade with foreign countries, and we can provide quick quotes, and offer the best solutions. The larger the order the more competitive our price!