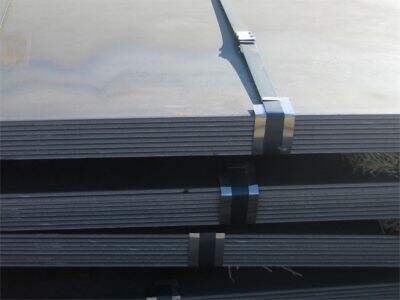

Steel sheet piles is used for building of strong structures like walls or bridges. Steel pile: The size of these steel sticks is pretty long and in the construction world, they are used extensively to support heavy objects for many years but also fight against forces from nature like wind or water. Nevertheless, there are various types and quality of steel sheet piles. This is why it can be challenging to choose the right steel sheet piles for your project. So before deciding as to which steel sheet pile might suit best for what you are planning, there some essential aspects that should be considered.

5 Factors To Be Considered For Steel Sheet Piles

Steel Sheet Piles Material: There are many types of steel used in the production process. Hot-rolled steel, cold-formed and possibly even recycled rescue vehicle types are among the popular choices that builders often use. Hot-rolled steel is known for its high strength capacity and can bear heavy loads, which make it great choice in many of the construction projects. Cold-rolled steel has a better surface finish but strength is not as high compared to the hot rolled sheet. Finally, cold-formed steel is also very cost-effective and light weight but it might not be as strong as some of the more traditional forms.

Soil Compatibility: The most important issue you must pay attention to when choosing steel sheet pile is the soil with which that material will work. In such cases, you may have to resort to materials which are more resistant (eg stainless steel or galvanised/ zinc coated sheet piles will be effective in resisting corrosion from very acidic soils. This will lower the chances of rust and give your building a better chance of staying strong and safe for longer.

Specifically, steel sheet piles come in varying shapes and sizes. The shape of the tailing forms is crucial because it dictates how much dirt they can support and their capacity to stand up against bending, buckling or rotating under load. Selecting the appropriate silhouette and size has to be perfect, so this guarantees your structure can bear all it requires.

Installation Method: Installation methods of steel sheet piles may also result in the type that you will want to use. Depending on specific project requirements, certain sheet piles can be driven into the ground relatively easily and others may instead more suitable for being pushed down. When choosing between the two, it would be helpful to know how both options are installed in order for you to make a better selection based on your project.

RelatedItemsCost: Last but not the least is cost of steel sheet piles that you will have to choose. The steel sheet pile price prices may change because of type, material size, and manufacturer. One thing that you need to consider when it comes to these materials is your budget and how much you want to spend.

Advantages and Disadvantage of Some Types of Steel Sheet Pile

Hot-Rolled Steel: Characterized by its high strength and durability. It is also highly non-corrosive so purposes such as heavy-duty construction would choose this material for what they need done. But it should be noted that the cost of hot-rolled steel sheet pile is higher than other types, and its surface is rougher (not suitable for application in all regions).

Cold-Rolled Steel:Cold-rolled steel sheet piles are smooth, new and relatively cheaper. They are a great solution for low-impact areas and smaller soil retention endeavors. While cold-rolled steel is likely to be more expensive for some forms it is actually weaker than hot rolled due to the processing of aluminum.if you need a particular form or gauge, this might not work out.

Cold-Formed Steel: Cold-formed steel sheet piles have light weight, which can make it more convenient to use and handle unlike other materials. This can be an enormous benefit if you are working on certain building projects. While these may come at a lower price, they might not be as durable (with larger-scale construction that has potential of lasting years)

Selecting the Ideal Integration for Your Project

Selecting the best steel sheet pile for your construction project is key to ensuring that you end up with what want. You will need to take into account, soil conditions how tall the build is going to be and deepness of water at that point also whether this needs to withstand impact in which case you would require steels built up structure or pan section property. Ehongsteel have experienced engineers that can give you professional advice and customized solutions based on your requirements.

What You Need to Know When Choosing Inexpensive Steel Sheet Piles

In terms of being cost effective, it should be the one which is going to have me pay for less in the long run rather than just looking at its initial value that I am about spend when buying those steel sheet piles. Of course the initial cost may seem like a good deal up front; however, that additional cost can quickly be made up should there ever need recognized maintenance, repairs or re-installation. Paying for a better grade of sheet pile from the outset, however, could be less costly overall and give you peace in mind. It will be considered the life-cycle costs of different steel piles including installation and maintenance.

Eco-friendly alternatives to the Steel Sheet Piles Explained

Sustainable construction trends are on the rise. Ehongsteel among other corporations are taking significant steps to create steel sheet piles from recycled metal. Plus, they manufacture with green processes. These practices reduce the carbon released during building. Additionally, construction and demolitions of old buildings can create steel scrap which when used is a part of recycle circle reducing the burden on environment.

Conclusion

To sum up, you should be very careful when selecting the steel sheet pile and culvert steel pipe to ensure that it can provide a structure that is safe as well as durable and cost-efficient. Soil compatibility, form and size, installation methods, cost factor are the few parameters must be considered when selection material & method for Gabion structures. Ehongsteel provides custom solutions for our clients to meet the requirements of your building and yet fully serves eco-purpose. With careful consideration through all of these aspects, you can ensure that your construction project will be a successful one and it will meet even beyond what is expected.