SPCD - Statistical Process Control (also known as 7QC Tools) plays a significant role in quality monitoring and improvements of products or services in business. Companies can set themselves up for success on the first try by leveraging SPCD, saving valuable time and resources that would be spent correcting mistakes further down the road.

There are several key practices that organizations need to follow in order ensure a successful engineering process from SPCD. The first and foremost, it is indeed important for businesses to identify their goals on the production of data while using them as a type of scale or ruler that would measure how they have fared in meeting these targets. Training all employees about the SPCD process and instilling a dedication to its implementation are also essential steps. In addition to this, it is important in establishing processes that can be changed and improved upon using the data obtained.

Data Collection and Analysis for Continuous Improvement within an organization This process allows businesses to identify the problem areas of inefficiencies, and from there enable targeted improvements. Teams identify and fix these issues, improving the quality of both their products as well as services. In addition, involving all employees in this process of improvement is very important across the organization as a whole because it shows that everyone influences to improve business operations.

No doubt, quality is something which can never be compromised and this holds even more value in today's competition. The modern consumer demands nothing less than perfection from the products and services they pay for, and businesses are surrounded by competitors in every corner. By providing a benchmark for companies, SPCD helps differentiate them with the promise of consistently delivering quality products and better services. It further helps in curtailing the expenditure by reducing waste and rework therefore a manufacturing firm can remain ahead of its competitors in the market with this methodology.

The process is managed and data analysis begins with an open, clear understanding of product or service outputs. Once these goals are set, collecting and analyzing the necessary data is crucial to know where one needs improvement. Once established, further refining of ongoing procedures may be rolled out to improve quality and reduce friction. It is crucial to get all employees involved in the QI process regardless of their position within an organization, as it provides a culture of further enhancement and using data gathered for organizational achievement. Following these detailed steps help in executing SPCD successfully and achieve quality related targets.

We SPCD supply American/British/Australian standard H-beams Japanese standard steel sheet piles and provide deep processing services such as punching and cutting Our products have been exported to Western Europe Oceania South America Southeast Asia Africa Middle East and many other regions

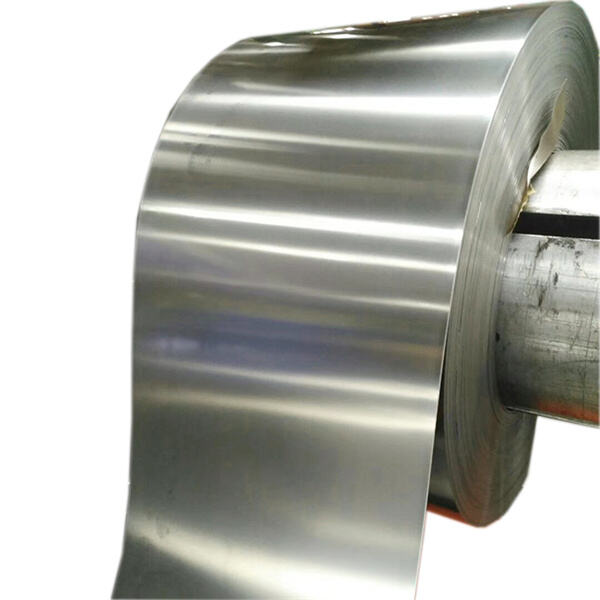

Our company has SPCD 17 years of experience in exporting steel We can provide an extensive range of coils and profiles. We also have a department that is specialized in export trade and can offer fast quotes as well as perfect solutions. The more you order the more affordable the cost will be!

Each product is inspected prior to shipping. Quality is guaranteed. The main products are all kinds of steel pipes SPCD/SSAW/LSAW/ galvanized/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

SPCD have a highly skilled foreign trade staff with top product expertise fast quote offering top-quality service We also have a highly skilled sales staff for customizing customers 24 hours for any inquiries questions as well as solutions We're certain that we'll be a reliable business partner for you